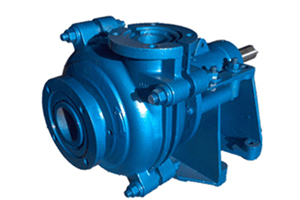

3/2C-TH Slurry Pump is a heavy-duty slurry pump that designed to handle the most abrasive and dense slurries. The 3/2C-TH slurry pump offers users a wide range of seal and liner configurations, allowing the pump to be fully customized to meet any specific application requirements. 3/2C-TH slurry pumps offer unmatched power consumption, long component life, and unmatched reliability.

Design Features:

√ Bearing assembly- large diameter shaft with short overhang contributes to long bearing life.

√ Liners – easily replaceable liners are bolted, not glued to the casing for positive maintenance.

√ Casing – casing halves of cast or ductile iron provide high operating pressure capabilities.

√ Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

√ Throat bush – wear is reduced and maintenance simplified by the use of tapered

RT® 3/2 C TH Slurry Pumps Performance Parameters:

Model | Max. Power (kw) | Materials | Clear Water Performance | Impeller Vane No. | |||||

Liner | Impeller | Capacity Q ( m3/h) | Head H (m) | Speed n (rpm) | Eff. η (%) | NPSH (m) | |||

3/2C-TH | 30 | M | M | 39.6~86.4 | 12~64 | 1300~2700 | 55 | 4~6 | 5 |

RT® 3/2 C TH Slurry Pumps Applications:

3/2 C TH Slurry Pump is suitable for processing the high abrasion slurry or the material containing solid particles.

Metal smelting plant: convey slurry

Sand plant: transporting and conveying sand and gravel, feeding sand and water all types of classification and dewatering plants

Coal preparation plant: classifying, screening and conveying heavy medium, conveying coal pulp

Ceramics and glass factory: porcelain clay and sandstone transportation, feeding hydrocyclone and effluent disposal etc.

Steel works: conveying slurry, rust and corrosive liquid etc.

Irrigation systems and dredging: silt removal in dams and river bed, sand classifying

Note: please specify if applied where oil and chemicals are contained

Note:

* RT® is a registered trademark and does not represent or is not in any way affiliated with Warman® of Weir Minerals Group. All names, numbers, symbols and descriptions are used for reference purpose only and do not imply that any pumps or parts listed is the product of Warman Pumps.

* RT® 3/2 C TH slurry pumps and spares are only interchangeable with Warman® 3/2 C AH slurry pumps and spares.

* This document is the property of RT® Pump and can be neither reproduced nor disclosed to a third party without a written authorization.