JYWQ series automatic mixing sewage pump adopts automatic mixing device on the basis of ordinary sewage pump. The device rotates with the motor shaft to produce extremely strong stirring force, stirring the sediment in the sewage tank into suspended matter, and sucking in The discharge inside the pump improves the anti-blocking and sewage discharge ability of the pump, completes drainage, cleaning, and desilting at one time, saving operating costs, and is an environmentally friendly product with obvious advancement and usability.

Main features

1. When the automatic stirring sewage pump is running, it will automatically stir the sediment at the bottom of the pool to completely prevent the accumulation of dirt without manual cleaning;

2. The unique impeller design has the function of shredding and tearing fibers and sundries;

3. Adopt the external circulation cooling system to make the sewage pump run at low water level, reduce the starting frequency of the motor and extend the life of the motor

4. Recommended products in the National Standard Atlas;

5. High-tech achievement transformation products.

JYWQ sewage pump model meaning

Example: 80JYWQ50-10-1600-3

80-discharge outlet diameter (mm)

JYWQ-automatic mixing sewage pump

50-flow (m3/h) 10-head (m) 1600-mixing range (mm) 3-motor power (KW)

The main purpose

1. Discharge of wastewater from factories and businesses seriously polluted.

2. Drainage systems of urban sewage treatment plants, hospitals, and hotels.

3. Sewage drainage station in residential area.

4. The water supply device of the drainage station of the civil air defense system and the water supply plant.

5. Municipal engineering, construction site.

6. Attached equipment for exploration, mining, and power plants.

7. Rural biogas digesters, farmland irrigation, and river pond dredging.

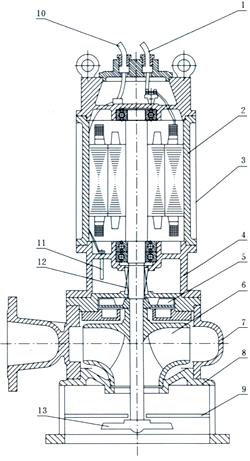

JYWQ sewage pump structure diagram

Description of structural features

| 1. The unique double-flow channel non-blocking impeller structure is adopted to improve the flow capacity and sewage discharge capacity of sewage. 2. The automatic stirring device produces extremely strong stirring power. The sediment in the pool is stirred into a suspended matter and then sucked into the impeller to discharge it to achieve the effect of dredging. 3. The partition divides the base into two, and mixing and water inflow do not affect each other. 4. The mechanical seal is a double-end mechanical seal, which is kept in the oil chamber for a long time to ensure the safe and reliable operation of the water pump. 5. The hydrodynamic seal of the auxiliary impeller structure not only has the auxiliary sealing function, so as to protect the mechanical seal, but also balance the axial force and prolong the service life of the bearing. 6. There is no water leakage detection probe in the connection cavity of the pump. When there is water leakage, the probe sends out a signal, and the control system protects the pump. The company can be equipped with a fully automatic safety protection control cabinet. 7. The motor stator adopts Class B and Class F insulation, and a thermal protector is built in. When the motor is overloaded and heats up, the protector will act in time to provide absolute protection to the pump and motor. 8. An oil-water probe is installed in the oil chamber. When the mechanical seal is damaged, water enters the oil chamber, and the probe sends a signal to protect the water pump by the control system. 9. JPWQ has an internal circulating cooling system to ensure that the water pump works normally at the low water level of the pool. | |||||

| 1 Main cable | 2 case | 3 Inner loop sleeve | 4 oil box | 5 expeller | 6 impeller | 7 Frame plate |

| 8 Base | 9 clapboard | 10 Oil-water control head | 11 Machinery Seal | 12.bearing | 13 agitator parts | |

Performance parameter table

model | discharge | max | max | agitator | speed | eff. | automatic | |

diameter | flow | head | diameter | |||||

(mm) | (m3/h) | (m) | (mm) | (r/min) | (%) | coupler | ||

1 | JYWQ50-12-15-1200-1.5 | 50 | 12 | 15 | 1200 | 2900 | 48 | CAK-50 |

2 | JYWQ50-20-7-1200-1.1 | 50 | 20 | 7 | 1200 | 2900 | 62 | CAK-50 |

3 | JYWQ50-10-10-1200-1.1 | 50 | 10 | 10 | 1200 | 2900 | 56 | CAK-50 |

4 | JYWQ50-15-15-1200-2.2 | 50 | 15 | 15 | 1200 | 2900 | 51 | CAK-50 |

5 | JYWQ50-25-10-1200-2.2 | 50 | 25 | 10 | 1200 | 2900 | 65 | CAK-50 |

6 | JYWQ50-15-20-1200-2.2 | 50 | 15 | 20 | 1200 | 2900 | 56 | CAK-50 |

7 | JYWQ50-20-15-1200-2.2 | 50 | 20 | 15 | 1200 | 2900 | 56 | CAK-50 |

8 | JYWQ50-42-9-1200-3 | 50 | 42 | 9 | 1200 | 2900 | 56 | CAK-50 |

9 | JYWQ50-17-25-1200-3 | 50 | 17 | 25 | 1200 | 2900 | 56 | CAK-50 |

10 | JYWQ50-25-22-1200-4 | 50 | 25 | 22 | 1200 | 2900 | 62 | CAK-50 |

11 | JYWQ50-40-15-1400-4 | 50 | 40 | 15 | 1400 | 2900 | 70 | CAK-50 |

12 | JYWQ50-25-32-1600-5.5 | 50 | 25 | 32 | 1600 | 2900 | 52 | CAK-50 |

13 | JYWQ50-40-30-1600-7.5 | 50 | 40 | 30 | 1600 | 2900 | 68 | CAK-50 |

14 | JYWQ65-25-15-1400-3 | 65 | 25 | 15 | 1400 | 2900 | 65 | CAK-65 |

15 | JYWQ65-37-13-1400-3 | 65 | 37 | 13 | 1400 | 2900 | 62 | CAK-65 |

16 | JYWQ65-25-28-1400-4 | 65 | 25 | 28 | 1400 | 2900 | 60 | CAK-65 |

17 | JYWQ80-40-7-1600-2.2 | 80 | 40 | 7 | 1600 | 2900 | 54 | CAK-80 |

18 | JYWQ80-29-8-1600-2.2 | 80 | 29 | 8 | 1600 | 2900 | 54 | CAK-80 |

19 | JYWQ80-43-13-1600-4 | 80 | 43 | 13 | 1600 | 2900 | 63 | CAK-80 |

20 | JYWQ80-50-10-1600-3 | 80 | 50 | 10 | 1600 | 1450 | 76 | CAK-80 |

21 | JYWQ80-40-15-1600-4 | 80 | 40 | 15 | 1600 | 2900 | 70 | CAK-80 |

22 | JYWQ80-60-13-1600-4 | 80 | 60 | 13 | 1600 | 2900 | 70 | CAK-80 |

23 | JYWQ80-35-25-1600-5.5 | 80 | 35 | 25 | 1600 | 2900 | 64 | CAK-80 |

24 | JYWQ80-50-25-1600-7.5 | 80 | 50 | 25 | 1600 | 2900 | 70 | CAK-80 |

25 | JYWQ80-50-30-1600-7.5 | 80 | 50 | 30 | 1600 | 2900 | 70 | CAK-80 |

26 | JYWQ100-80-9-2000-4 | 100 | 80 | 9 | 2000 | 1450 | 62 | CAK-100 |

27 | JYWQ100-110-10-2000-5.5 | 100 | 110 | 10 | 2000 | 1450 | 71 | CAK-100 |

28 | JYWQ100-70-15-2000-5.5 | 100 | 70 | 15 | 2000 | 1450 | 71 | CAK-100 |

29 | JYWQ100-100-15-2000-7.5 | 100 | 100 | 15 | 2000 | 1450 | 73 | CAK-100 |

30 | JYWQ100-80-20-2000-7.5 | 100 | 70 | 20 | 2000 | 2900 | 71 | CAK-100 |

31 | JYWQ100-50-35-2000-11 | 100 | 100 | 35 | 2000 | 2900 | 68 | CAK-100 |

32 | JYWQ100-70-22-2000-7.5 | 100 | 80 | 22 | 2000 | 2900 | 70 | CAK-100 |

33 | JYWQ100-100-22-2000-15 | 100 | 150 | 22 | 2000 | 1450 | 61 | CAK-100 |

34 | JYWQ100-80-30-2000-15 | 100 | 210 | 30 | 2000 | 1450 | 67 | CAK-100 |

35 | JYWQ150-150-10-2000-7.5 | 150 | 250 | 10 | 2000 | 1450 | 75 | CAK-150 |

36 | JYWQ150-210-7-2500-7.5 | 150 | 150 | 7 | 2500 | 1450 | 78 | CAK-150 |

37 | JYWQ150-250-6-2500-7.5 | 150 | 200 | 6 | 2500 | 1450 | 79 | CAK-150 |

38 | JYWQ150-150-15-2500-11 | 150 | 65 | 15 | 2500 | 1450 | 79 | CAK-150 |

39 | JYWQ150-200-10-2500-15 | 150 | 180 | 10 | 2500 | 1450 | 73 | CAK-150 |

40 | JYWQ150-65-40-3200-18.5 | 150 | 150 | 40 | 3200 | 1450 | 58 | CAK-150 |

41 | JYWQ150-180-22-2600-18.5 | 150 | 110 | 22 | 2600 | 1450 | 75 | CAK-150 |

42 | JYWQ150-150-26-2600-18.5 | 150 | 300 | 26 | 2600 | 1450 | 72 | CAK-150 |

43 | JYWQ150-110-30-2600-18.5 | 150 | 130 | 30 | 2600 | 1450 | 72 | CAK-150 |

44 | JYWQ150-300-15-2600-22 | 150 | 100 | 15 | 2600 | 1450 | 76 | CAK-150 |

45 | JYWQ150-130-30-2600-22 | 150 | 300 | 30 | 2600 | 1450 | 70 | CAK-150 |

46 | JYWQ150-100-40-3000-30 | 150 | 250 | 40 | 3000 | 1450 | 64 | CAK-150 |

47 | JYWQ200-300-7-3000-11 | 200 | 300 | 7 | 3000 | 1450 | 75 | CAK-200 |

48 | JYWQ200-250-11-3000-15 | 200 | 250 | 11 | 3000 | 1450 | 72 | CAK-200 |

49 | JYWQ200-300-10-3000-15 | 200 | 300 | 10 | 3000 | 1450 | 75 | CAK-200 |

50 | JYWQ200-250-15-3000-18.5 | 200 | 250 | 15 | 3000 | 1450 | 72 | CAK-200 |

51 | JYWQ200-400-10-3000-22 | 200 | 400 | 10 | 3000 | 1450 | 75 | CAK-200 |

52 | JYWQ200-200-20-3000-22 | 200 | 200 | 20 | 3000 | 1450 | 73 | CAK-200 |

53 | JYWQ200-250-22-3000-30 | 200 | 250 | 22 | 3000 | 1450 | 73 | CAK-200 |

54 | JYWQ250-600-7-3000-22 | 250 | 600 | 7 | 3000 | 1450 | 78 | CAK-250 |

55 | JYWQ250-600-9-3000-30 | 250 | 600 | 9 | 3000 | 1450 | 78 | CAK-250 |

Precautions

(1) Use a megohmmeter to check the insulation resistance of the stator winding of the motor to the ground before operation, and the value shall not be less than 50 megohm

(2) Check whether the cable is damaged or broken. If it is damaged, it must be replaced in time to avoid leakage; the cable section should match the current.

(3) When the voltage exceeds ±10% of the rated voltage, the electric pump shall not be started.

(4) To ensure safe use, the grounding wire in the four-core cable must be reliably grounded to prevent electric shock accidents.

(5) When the electric pump is submerged in the water, it should be lifted vertically, and it is not allowed to lay on the ground horizontally, let alone sink into the sludge. When stopping use, the electric pump should be lifted and cleaned, placed in a dry place, and take care to prevent freezing.

(6) It is forbidden to use the cable as a lifting rope for installation.

(7) Check the running direction of the rotor, it should rotate clockwise from top to bottom.

(8) Outdoor switches or terminals should be protected from rain and moisture. It is forbidden to touch the switch with wet hands or barefoot to prevent electric shock.

(9) When moving the electric pump, the power supply must be cut off, and people must not touch the water source when the electric pump is running to prevent personal accidents from leakage.

(10) It is strictly forbidden to run the motor under phase loss. If the fuse is found to be blown, you should check the cause before continuing to use it. The fuse should not be thickened arbitrarily.

(11) When the pump is running, it should be managed by a special person. If any abnormality is found, it should be shut down immediately for inspection and troubleshooting. (Refer to the case of fully automatic protection cabinets).

(12) After the electric pump has been in normal operation for half a year under the specified working medium conditions, check the sealing condition of the oil chamber. If the oil in the oil chamber is milky or has water precipitation, replace the No. 10-20 mechanical oil and mechanical seal in time. For electric pumps used under severe working conditions, they should be overhauled frequently.

(13) The user should select the appropriate flow head according to the actual operating conditions to achieve the best use effect. The parameters shown on the pump nameplate or manual are the best operating conditions, and the user can choose (0.7~1.2) times better Use within the flow, prohibit the use of excessive flow, otherwise the flow is too large, and the head is too low, which will easily overload the motor.